Secure online shopping

Technical Manual

Pump Installation and Operating Instructions

|

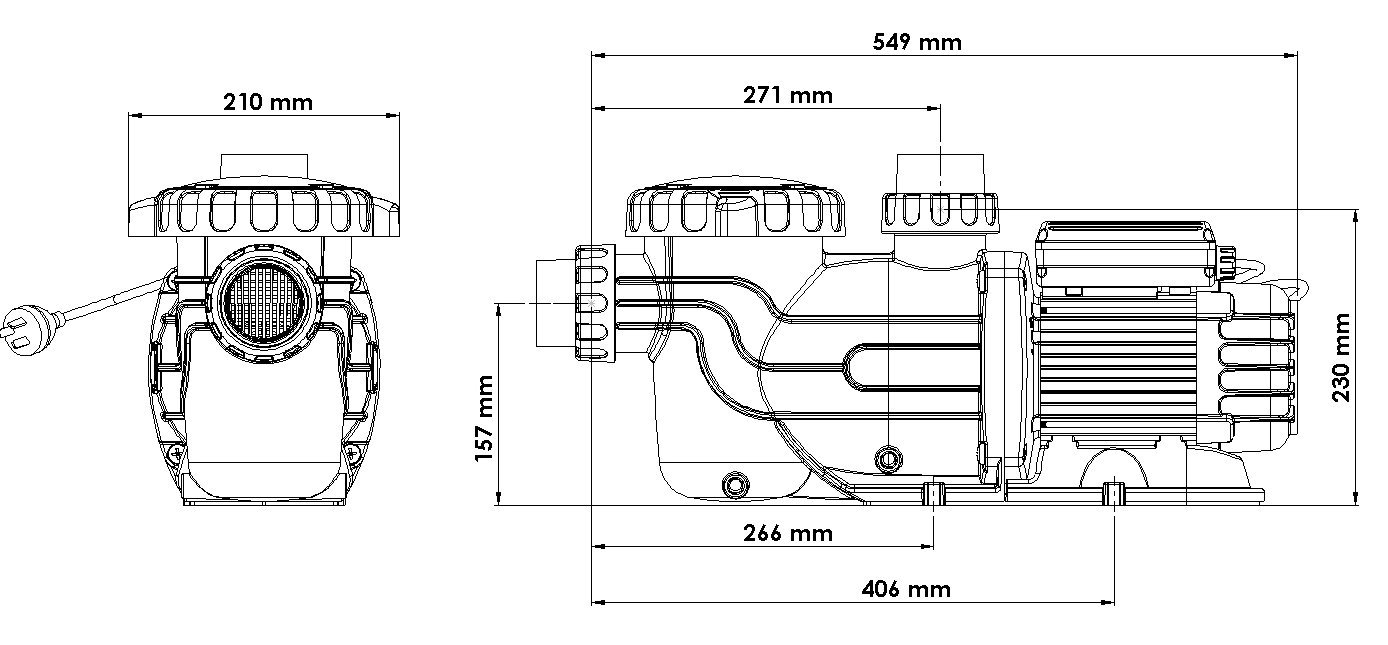

Pump Model |

Hp |

Supply Voltage |

Power (watts) |

Current (amps) |

Width (mm) |

Height (mm) |

Length (mm) |

Lpm @ 6m |

Lpm @ 10m |

|

Pulse 070 |

1.0 |

230-240 |

750 |

4.4 |

210 |

230 |

549 |

330 |

265 |

|

Pulse 090 |

1.25 |

230-240 |

925 |

5.6 |

210 |

230 |

574 |

370 |

290 |

|

Pulse 110 |

1.5 |

230-240 |

1100 |

6.2 |

210 |

230 |

574 |

400 |

320 |

Electrical Approval SGS 130772-EA Noise Rating 65 dB (1m)

1. General

2. Installation of the Pulse Pool Pump

Edgetec Systems Pty Ltd has applied the latest CAD and CFD software in designing your Pulse Pool Pump to ensure that you have many years of trouble free operation. Here are some simple installation rules that should be followed when installing the Pulse pool pump;

1. Care should be taken to position the pump so that it has adequate drainage. Ensure the motor cannot become immersed or flooded and the pump location should be well ventilated. The pump should be protected from direct sunlight and weather.

2. Ensure that the pump is secured onto a stable base. The pump mounting foot has mounting points where the pump can to be bolted to the base to prevent movement.

3. The pump foot has an anti-vibration pad moulded into the base to minimise noise and vibration. Failure to secure the pump to the base securely may cause damage and void the warranty.

4. The pump must be accessible for maintenance and be easily removed for service. Ensure that you allow enough area around the hair and lint pot basket for removal and cleaning.

5. The pump suction line requires a minimum of 50mm PVC pipe and should be kept as short as possible with the minimum number of elbows and bends and no air trap for optimum performance. The suction line must be installed below the water level until just in front of the pump location and the vertical riser used to reach the pump inlet. Note: Wear protective gloves when using PVC glue and solvents and always allow 24 hours to dry before starting the pool pump.

6. The suction and return pipe work should be self-supported so that no strain from the pipework loads up the pump barrel unions. The pump should not be suspended by the pipe work or other equipment as this will cause leaks and eventual damage to the pump. Only use the barrel unions supplied with the pump, barrel unions only require to be hand tight, do not use tools to tighten the barrel union nuts.

7. If the pump is installed below the water level - isolation valves must be fitted to the suction and return lines.

8. Pump installations that are 500mm or more above the water level will require a foot valve at the pool or a check valve in the suction line.

9. Water temperature must not exceed 45°.

3. Electrical Connection

1. IMPORTANT! - The electrical installation must be performed by a licensed electrician and must conform to all national, state and local codes. Australian Wiring Rules AS3000

2. The PULSE pump must be supplied through a residual current device (RCD) with a rated residual operating current of 30mA.

WARNING

If the supply cord is damaged it must be replaced by Edgetec Systems or its service agent or a suitably qualified person.

Never run your spa pump without water as this can cause serious damage to the mechanical seal which may cause the spa pump to leak. Running the pump without water will void your warranty

4. Operation-Priming

The Pulse series pool pump has been designed to prime and re prime as long as the Strainer Basket is full of water and there is adequate supply from the suction points.

Priming/Start up

1. If the pump is installed above the water level and the Strainer Basket has no water in the bowl, close off the valve in the suction line (if fitted), remove the Strainer Basket lid, and fill the bowl with water to the lowest level of inlet pipe. Replace the Strainer Basket lid ensuring that its fitted correctly- see Strainer Basket - Maintenance below.

2. If the pump is installed below the water level, open the valves and you should see the water flow freely into the hair lint pot bowl.

3. Switch the pool pump on.

4. The pump should now be primed and running; however, on some installations the priming time may alter depending on the elevation and the length of pipe on the suction line.

5. If after around 90 seconds the pump has not primed switch the pump off and repeat step 1. If after a number of attempts the pump does not prime - check your connections for any leaks, it may be necessary to fit a foot or check valve to obtain prime.

5. Strainer Basket - Maintenance

Your Pulse series pool pump has been designed to run for extended periods of time, however, the Strainer Basket should be inspected and cleaned on a weekly basis or more regularly if required, to do this follow the steps below;

1. Turn the power off to the pump and close the isolation valves.

2. Undo the Strainer Basket lid by turning the Strainer locking ring in an anticlockwise direction (approximately 1/8 of a turn) and remove the locking ring and Strainer Basket.

3. Clean the debris from the basket and clean with water if required.

4. Refite the Strainer Basket into the pump aligning the open section of the basket with the inlet of the pump. If the basket is not fitted correctly the Strainer lid will not seal airtight and pump may not prime.

5. Fill the Strainer Basket with water to the lowest level of inlet pipe (if required). and

6. Replace the Strainer Basket locking ring and tighten in a clockwise direction approximately 1/8 of a turn.

Hand tighten the lid only, do not use any tools to tighten the lid.

7. Open the isolation valves and switch the pump on.

6. General Maintenance

1. On a monthly basis check the area around the pump motor to ensure that it is clear of debris, i.e. leaves, sand and dirt etc. Failure to keep this area clean may cause the pump fan cowl to become blocked and cause the pump to overheat.

2. Check the Strainer Basket regularly, blocked Strainer Basket or suction line will limit the water to the pool pump and may cause serious damage and void your warranty.

3. On a monthly basis check the O rings on your Strainer Basket lid and pump barrel union O rings for leaks. Should any leak be detected, clean and regrease the O Rings or replace if required. Use a Silicone Based grease - Do not use petroleum based grease or Vaseline.

4. Check under your pump every 3 months to ensure that it is not leaking; if a leak is found call a pool service technician for repair.

5. Maintain your water and chemical balance.

6. Do not add salt, chlorine, acid or any chemicals directly into your skimmer box, this may cause damage to your pump and possibly void your warranty.

7. If there is large amounts of sand or grit in your pool always use a filter sock in your hair and lint pot basket, otherwise the sand and grit passing through your pump could cause serious damage.

8. In cold climates where the pool pump maybe subject or exposed to frost or freezing, we recommend that the pump not be used during this time and that the water be drained completely. There is a drain point located on the hair and lint pot and a ¼ BSP drain plug can be sourced from Edgetec Systems. Fitting this plug requires drilling out the wall and tapping 1/4 BSP thread.

9. Should your pool pump require servicing and you cannot locate a service person, please contact Edgetec Systems for their nominated service outlet.

10. Use only genuine Edgetec parts when replacing or maintaining your pool pump.

7. Trouble Shooting Guide

|

Symptoms |

Possible Cause |

Remedy |

|

Pump will not prime. |

No water in the pump. |

Ensure that the Strainer Basket is full to base of Pump inlet Ensure water level is correct in the pool |

|

Skimmer Basket not keyed to Pump |

Remove Strainer Lid. Check the Strainer Basket is correctly fitted to the Key slot in the pump. See below

.

|

|

|

Air leak in Suction Pipe Line. |

Ensure that the water level is correct at the suction points. Tighten all barrel unions and fittings in suction line of the pump. |

|

|

Low Flow. |

Blocked lined or closed valves. |

Check that all the valves are in the open position. Check that the skimmer and/or strainer basket are free from debris. |

|

Ensure that the pump impeller is not jammed or blocked. |

||

|

Pump will not run. |

Dirty Filter.

|

Sand Filter - Check and backwash filter. Cartridge Filter- remove and clean cartridge element. |

|

Blocked Suction |

Blocked Skimmer basket and/or strainer basket. Check and clean both baskets. |

|

|

Valves in closed position. |

Open the valves.

|

|

|

No mains power. |

Check to ensure that the power point is switched on. Ensure that the RCD has not tripped. Check that the time clock (if fitted) on other equipment is set correctly. |

|

|

Pump cuts out on thermal over load. |

Jammed pump impeller. |

Switch the power off to the pump, see if the pump shaft spins freely by rotating the pump shaft at the back of the pump motor. If still jammed consult you pool service technician or Edgetec. |

|

Motor Overheating Inadequate Ventilation |

Check that the motor fan is free from debris and has clear space around back of motor.

Check that the pump is not in direct sunlight.

|

|

|

Noisy Pump. |

Low or incorrect voltage.

|

Have an electrician check the power supply to the pump. |

|

Ensure that the pump is not running off an extension lead. Extension Lead can have excessive voltage drop. |

||

|

Motor bearings.

|

Have the motor bearing checked by an authorised person or Edgetec. Replace if necessary. |

|

|

Foreign matter in the pump impeller |

Remove and dismantle pump and clean foreign matter from impeller. |

|

|

Air leak |

Check that there is no air leaks in the suction line causing the pump to cavitate. Tighten all fittings. |

Pulse Pool Pump Spare Parts Listing